-

- Cnc Machine

- Machining

- Machining Shops

- What Is Electric Discharge Machining

- Water Machining

- Slotting Machining

- Milling Machining

- Machining Slots

- Machining Operator

- Machining Milling

- Machining Grinding

- Machining Cnc

- Lathe Machining Part

- Injection Molding Machining

- Horizontal Machining Centers

- Electron Beam Machining

- Electric Discharge Machining

- Computer-aided Machining

- Computer Numerical Control Machining

- Bore Machining

- Milling

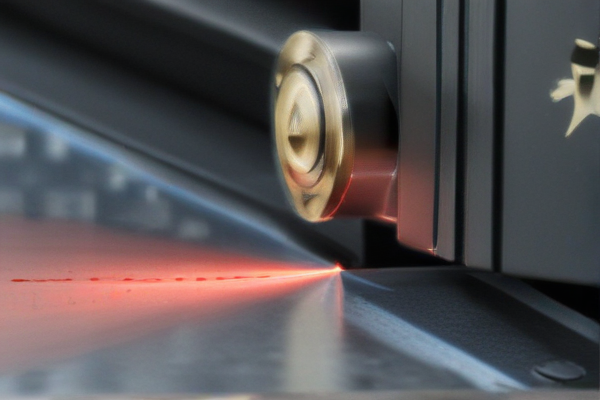

- Laser Cutting Machine

- Welding Laser Machine

- Metal Laser Cutting Machines

- Metal Cutting Laser Machine

- Laser.cutting Machine

- Metal Cutter Laser Machine

- Laser Metal Cutting Machine

- Laser For Cutting Machine

- Laser Cutting Metal Machine

- Laser Cutting Machines Metal

- Laser Cutting Machine For Steel

- Laser Cutting Machine For Metals

- Laser Cutting Machine For Metal

- Laser Cutter Metal

- Laser Cutter

- Engraver Laser

- Contact

- Newsletter

- Whatsapp 8615951276160

- Cnc Machine

- Machining

- Machining Shops

- What Is Electric Discharge Machining

- Water Machining

- Slotting Machining

- Milling Machining

- Machining Slots

- Machining Operator

- Machining Milling

- Machining Grinding

- Machining Cnc

- Lathe Machining Part

- Injection Molding Machining

- Horizontal Machining Centers

- Electron Beam Machining

- Electric Discharge Machining

- Computer-aided Machining

- Computer Numerical Control Machining

- Bore Machining

- Milling

- Laser Cutting Machine

- Welding Laser Machine

- Metal Laser Cutting Machines

- Metal Cutting Laser Machine

- Laser.cutting Machine

- Metal Cutter Laser Machine

- Laser Metal Cutting Machine

- Laser For Cutting Machine

- Laser Cutting Metal Machine

- Laser Cutting Machines Metal

- Laser Cutting Machine For Steel

- Laser Cutting Machine For Metals

- Laser Cutting Machine For Metal

- Laser Cutter Metal

- Laser Cutter

- Engraver Laser

- Contact